Table of Contents

Imagine you’re cruising across the water, the sun on your face, and your boat performing flawlessly. Now imagine that dream interrupted by an unexpected leak or mechanical failure, all because of a neglected, worn-out part you barely knew existed. Enter boat bellows, the small yet mighty components that keep your watercraft running smoothly and protected from water damage. These flexible seals are the unsung guardians of your boat’s engine and drive system, and choosing the right ones can make all the difference. Choosing quality boat bellows can mean the difference between seamless operation and costly repairs. In this guide, we’ll dive into why investing in the best boat bellows is essential for your watercraft’s longevity and how they contribute to a worry-free experience on the water. Let’s explore how quality boat bellows ensure seamless watercraft maintenance, so your adventures never skip a beat.

What Are Boat Bellows?

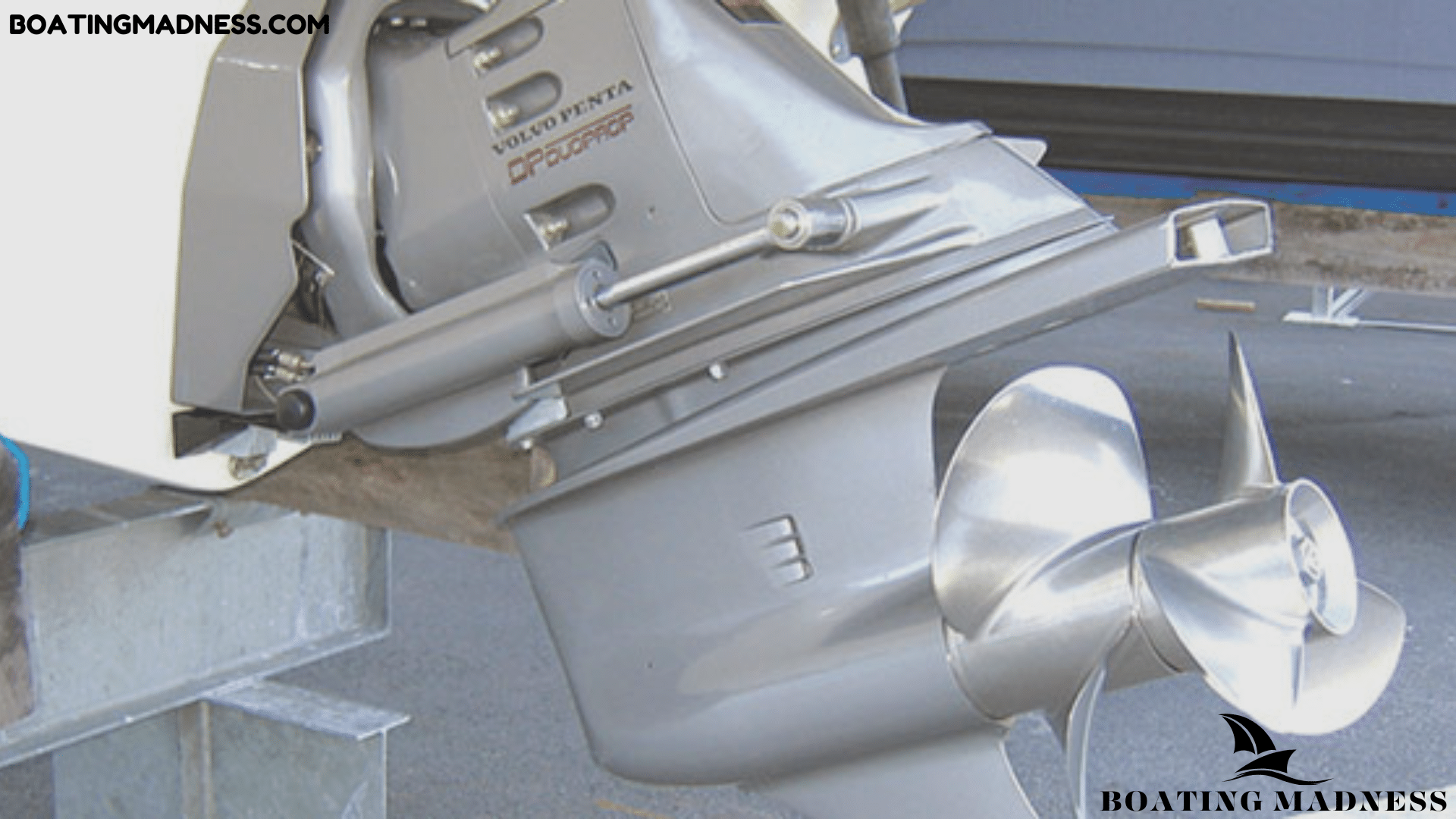

Boat bellows are flexible gaskets that bridge the gap between moving and stationary parts of a boat’s drive system. Found in inboard/outdrive (sterndrive) vessels, these components shield the mechanical systems from water, debris, and other harmful substances while allowing movement and flexibility. Made from durable rubber or synthetic materials, bellows withstand the harsh marine environment, including salt exposure, temperature changes, and mechanical wear.

Bellows protect critical systems like the exhaust, shift cable, and gimbal bearing. For instance:

- Gimbal Bearing Bellows: Shield the gimbal bearing and housing, ensuring smooth tilting and rotation of the sterndrive.

- Shift Cable Bellows: Protect the cable that links the control lever to the drive system, preventing corrosion and maintaining smooth gear shifting.

- Exhaust Bellows: Safely channel exhaust gases out of the boat while preventing backflow that could flood the engine.

Without functioning bellows, water intrusion can cause rust, corrosion, and mechanical failures, leading to costly repairs and downtime. Regular inspections and proactive maintenance are essential to prevent these issues.

Types of Boat Bellows and Their Functions

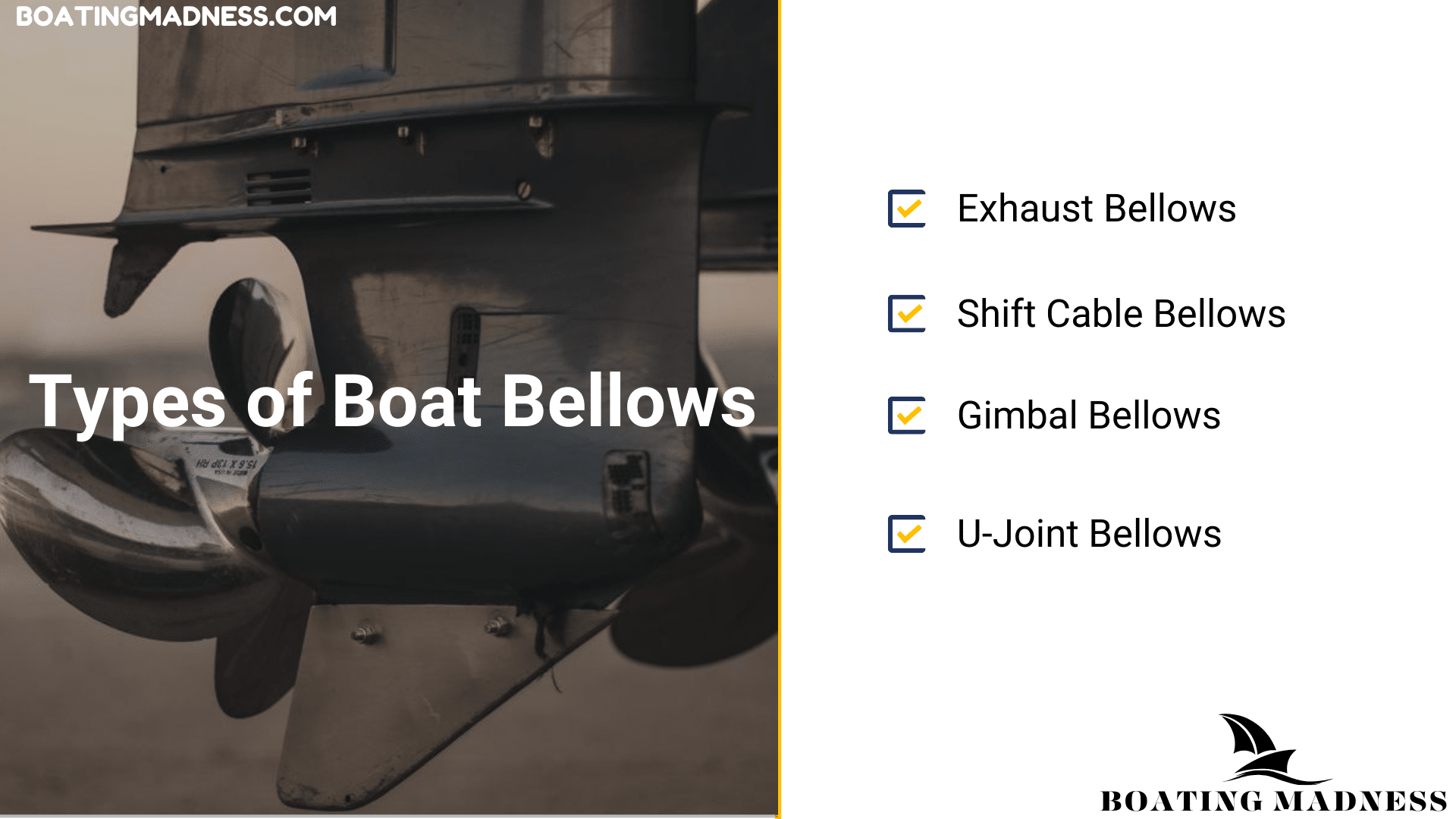

Different bellows serve specific purposes in maintaining your boat’s safety and performance:

- Exhaust Bellows: Divert engine exhaust gases and prevent water backflow. They provide flexibility to accommodate engine movement while protecting the hull from harmful gases.

- Shift Cable Bellows: Cover and protect the shift cable, maintaining its functionality and preventing water ingress that could cause corrosion and failure.

- Gimbal Bellows: Guard the gimbal bearing and housing against water and debris, ensuring the sterndrive pivots smoothly without damage.

- U-Joint Bellows: Protect the universal joints connecting the engine to the drive shaft. By keeping water out, they prevent rust and maintain the reliability of the drive system.

Signs of Bellows Failure

A failing bellows system often shows clear signs, the most common being leakage. Water seeping into the engine room or other areas can cause severe damage, including corrosion of vital components like the gimbal bearing or shift cable.

Watch for these indicators of impending failure:

- Cracks, shrinkage, or stiffness in the bellows material.

- Visible leaks or water accumulation in areas protected by bellows.

- Difficulty in shifting gears or unusual noises from the drive system.

Early detection and timely replacement of damaged bellows can prevent costly repairs and ensure the safety of your boat and passengers.

Maintaining and Replacing Boat Bellows

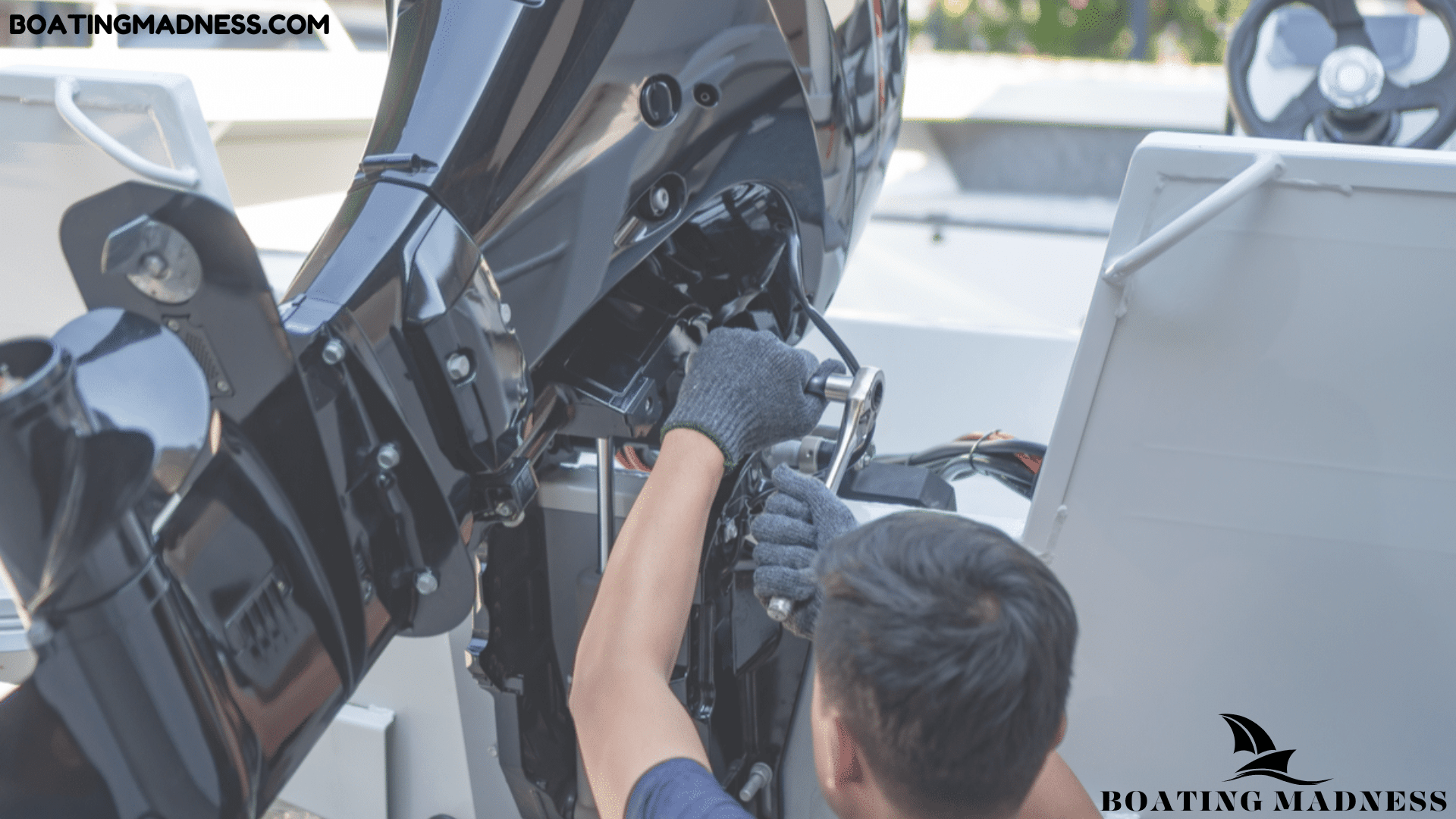

Proactive maintenance and replacement of worn bellows are critical for the longevity of your boat’s propulsion system. Here’s a step-by-step guide for replacing boat bellows:

- Remove the Drive: Detach the boat’s drive unit by loosening screws and releasing the trim cylinder for better access to the bellows.

- Cut Away Old Bellows: Carefully remove the damaged bellows using appropriate tools, ensuring no harm to surrounding components.

- Install Replacement Bellows: Position the new bellows securely onto the drive shaft and gimbal housing. Tighten all connections to prevent water intrusion.

- Replace Shift Cable Bellows: If needed, replace the shift cable bellows to ensure seamless gear operation and water protection.

- Inspect and Test: After installation, thoroughly check seals and connections for leaks. Perform a test run to confirm the system is functioning correctly.

Cost of Bellows Replacement

The cost of replacing boat bellows varies depending on the type, material, and labor involved. Bellows replacement generally ranges from $200 to $1,200. Additional expenses may arise if related components like the gimbal bearing or shift cable also require replacement.

It’s advisable to consult a marine technician to assess your boat’s specific needs and obtain an accurate estimate.

Preventive Measures for Longevity

Beyond routine inspections, preventive care can extend the life of your boat bellows:

- Lubrication: Apply marine-grade silicone lubricant to reduce wear and ensure smooth operation.

- Cleaning: Keep bellows free of debris and marine vegetation to prevent damage.

- Alignment Checks: Ensure the boat’s alignment is correct to avoid premature wear on bellows.

- Anodes Installation: Use sacrificial anodes to protect bellows from galvanic corrosion, especially in salty environments.

Conclusion

Boat bellows are unsung heroes in maintaining your watercraft’s safety, reliability, and performance. Regular maintenance, timely replacement, and preventive measures ensure their functionality, safeguarding critical systems from water intrusion and environmental damage.

By incorporating these practices into your boating routine, you enhance the longevity of your vessel’s propulsion system, reduce repair costs, and enjoy safer, more enjoyable experiences on the water. For every boat owner, understanding and caring for bellows is an essential part of responsible and rewarding boat ownership.